Categories

- Blog (58)

- News & Events (34)

Cummins Engine Cylinder Deactivation (CDA)

Focus on zero carbon

Cummins continues to invest in key technologies

reduce greenhouse gas emissions

and reduce the impact of its products on air quality

Developed by all members of the Cummins family

Engine Cylinder Deactivation (CDA)

in reducing nitrogen oxides and carbon dioxide emissions

achieve new breakthroughs

Power diesel and natural gas engines

while further improving fuel efficiency

Significantly lower emissions

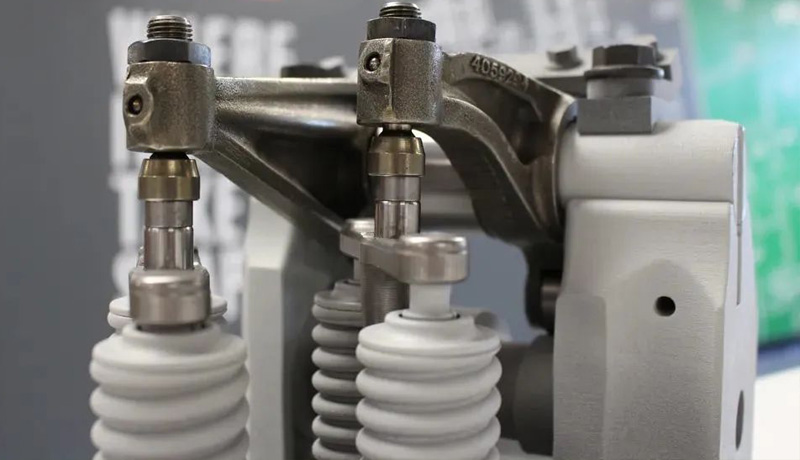

The cylinder deactivation technology uses mature components to make the engine valve of the selected cylinder no longer work under certain working conditions, so that the engine can achieve better fuel economy. Still-operating cylinders achieve higher exhaust temperatures, keeping the aftertreatment system hot at low loads and at start-up, reducing NOx emissions.

Reduces pumping losses and friction work, improving fuel economy

Faster warm-up of engine and aftertreatment system

Optimized combustion and reduced fuel consumption in firing cylinders

Under low load conditions, keep the aftertreatment system at a high temperature to improve emission performance

Reduced cooling losses in aftertreatment during coasting

Hydraulic drive mechanism integrated in the push rod or valve axle for high system integration

Modular design connected with high-power braking technology for efficient module upgrades

Engine braking and cylinder deactivation technologies provide strong technical support for meeting current and future emission regulations. Jacobs is a significant supplier of engine braking, cylinder deactivation, start-stop and thermal management technologies, and its deep engineering capabilities, innovative products combined with Cummins will create new technological innovations and growth opportunities to further advance the company’s The zero-carbon strategy helps Cummins provide more diverse and better solutions for global users.