Categories

- Blog (58)

- News & Events (34)

The fourth stage of non-road is coming, how is Cummins preparing for core component product technology? What role do components play on the road to zero carbon?

Parts business is an important foundation for Cummins’ continued success in the Chinese market and a key part of its global business growth strategy.

Talking about the current market layout and overall market situation of Cummins parts and components, Chai Yongquan, general manager of Cummins parts business department in China, said that around the three strategic directions, namely core business, adjacent business and new energy business, Cummins parts business has grown in recent years. A number of acquisitions have been achieved, forming a complete power chain product and technology system ranging from turbocharging, fuel systems, brakes and after-treatment businesses, as well as Eaton Cummins transmissions and Cummins Meritor axles, as well as the newly established software and electronic business.

“The entire parts business actually spans almost all the core parts of Integrated Power. We hope that we can continue to make efforts in the parts business and provide more complete parts system solutions.”

Chai Yongquan pointed out, “Relying on core components to create top reliable products in the industry and create greater value for customers, this is also the direction that Cummins has always adhered to.” Facing the emission upgrade of non-road China IV standards, the high reliability of Cummins’ core components Sex will play an important role for customers. Its value comes from the following five aspects:

First, the product performance meets the corresponding emission requirements, especially the post-processing technology is ahead of the industry;

Second, the product quality is very good;

Third, coordinate the resources of all parties to meet the needs of Chinese customers;

Fourth, the service preparations are sufficient, whether it is service spare parts or terminal service provider training, everything is comprehensive;

Fifth, the cost of integrating products into the entire value chain is more value for money.

“All the business units of our Components Division have greatly improved their overall competitiveness through product design optimization, procurement cost reduction, optimization of internal management operations, and efficiency improvement.”

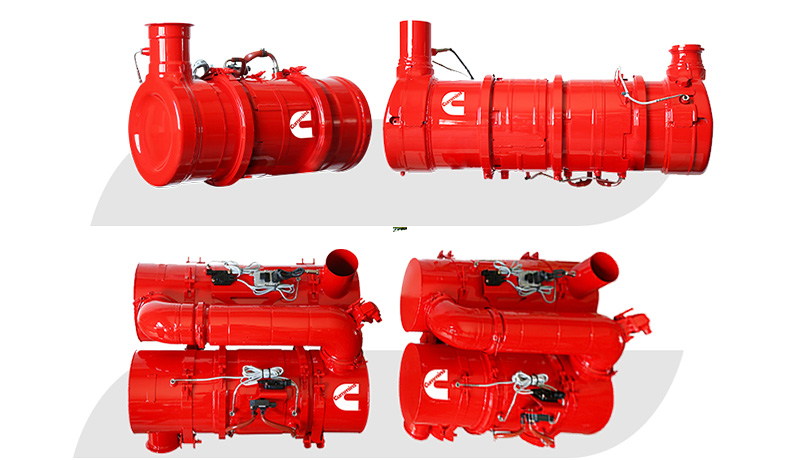

Cummins has a unique exhaust after-treatment technology, which is far ahead in the current non-road power industry. Specifically, Cummins emission treatment system has more than 20 years of product development and application experience in China IV after-treatment technology, SCR (Selective Catalytic Reduction), DPF (Diesel Particulate Filter) and DOC (Diesel Oxidation Catalyst) ) have passed hundreds of billions of kilometers of product verification.

Chen Jian, general manager of Cummins China’s emission treatment system, pointed out that its leading position in the industry and the intelligence and efficiency of its technology are mainly reflected in the following aspects:

First of all, it is ahead of the industry in terms of software and hardware, post-processing technology itself and management of emissions.

Furthermore, Cummins after-treatment technology has achieved a high degree of integration, while emissions pay more attention to durability.

In addition, relevant functions of intelligent diagnosis are integrated, such as reminding users of information such as oil quality and sulfur content.

Non-road national IV emissions put forward higher requirements for oil products, urea, and diagnostic and maintenance cycles. From the perspective of users, they will worry about the increase in costs. General Manager Chen Jian said that although the initial purchase cost will increase, from the point of view of the entire life cycle of the product, as the overall fuel consumption decreases, the product’s “economical and energy-saving” advantages will become more prominent, and the product’s operating cost will be greatly reduced. , will bring more benefits to our customers.

In addition, Cummins also strongly appeals to industry customers to use qualified oil products. In the long run, this will reduce equipment failure and component damage, and make product performance more stable.

The reliability of components is an important foundation for Cummins to gain a foothold in the industry for a long time, and it is also the focus of end users. So, how does Cummins build components with high reliability? Cai Songli, China Chief Engineer of Cummins Components Division, used a key word, that is “heart”.

Cummins non-road China IV power solution highlights its new strategic thinking of customized development for the application environment. Based on rich experience in global R&D and product application, it is tailored for different markets. “Create Cummins products that fully adapt to actual working conditions for our customers, and maximize the high reliability of the products.”

In the face of this non-road country IV emission upgrade, Cummins has sufficient technical reserves in non-road country IV. Cai Songli said that the product conception began in 2017, and after more than four years of R&D work, Cummins has done a lot of work in terms of overall product design and detailed technology of post-emission treatment. “In addition to the high reliability of the product, we also apply a digital and intelligent control system to the product to make it more intelligent, energy-saving, and more durable!”

For non-road equipment that has entered the National IV stage, relying on the service data base of millions of vehicles, Cummins has achieved new breakthroughs in predictive fault diagnosis. At present, Cummins’ predictive fault diagnosis can achieve service early warning, pre-diagnosis analysis, software upgrade and intelligent diagnosis and maintenance.

“Cummins’ predictive fault diagnosis can enable active repair. When a fault code prompt appears on the user end, we will actively remind the user to check in time to avoid some major faults. In particular, the system will remind the user that the oil or urea used Eligibility.”

Facing the future journey of the zero-carbon goal, Cummins will continue to develop integrated power technology and improve the high reliability of core components. Power solutions and all-round support meet the needs of Chinese customers for continuous iterative upgrades, and at the same time help customers reduce carbon emissions throughout their life cycle.