Categories

- Blog (58)

- News & Events (34)

Guangxi Cummins Industrial Power Co., LTD. (GCIC) is a joint venture between Cummins (China) Investment Co., Ltd. and Guangxi Liugong Machinery Co., LTD., which is located in Liuzhou city, Guangxi Zhuang Autonomous Region and registered on June 27, 2012.

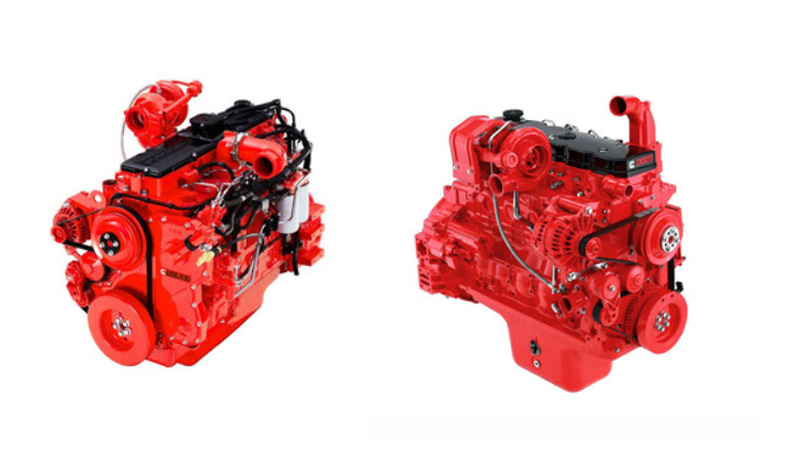

Cummins in guangxi is an important part of the global production system of cummins, comprehensive use of cummins development platform, operating system and quality management system, combining with the characteristics of engineering machinery performance and requirements, tailored exclusive power of engineering machinery, production cummins QSB7 series and L9.3 / QSL9.3 series engineering machinery in the exclusive horsepower diesel engine, Meet China’s non-road II/III, European Stage IIIA and US Tier 3 emission standards, and have the ability to upgrade to Stage IV emissions.

Our products:

• In March 2013, the first L9.3 mechanical engine with 5-ton loader went on sale;

• In October 2013, QSB7 electronic control engine equipped with 20-30 ton excavator began to be marketed and sold, which was well received by customers;

• In October 2015, QSL9.3 electronic control engine with 5-ton loader was successfully released and launched. Relying on The mature electronic control technology of Cummins, it successfully led the three-stage emission technology upgrade and intelligent trend of China’s construction machinery industry.

Our advantages:

• Polymerization Cummins has nearly 100 years of r&d and manufacturing experience

• Continue to innovate and maintain technological superiority

• Excellent manufacturing system, advanced assembly technology and equipment

• Use cummins efficient supply chain system

• With cummins global after-sales service system, provide quality and fast after-sales service

Guangxi cummins industrial power co., LTD. Is a construction machinery provide exclusive diesel engine power of high-tech enterprises, has a number of invention patents, inheritance of cummins technology accumulation in one hundred, according to the characteristics of the engineering machinery homework to tailor, developed B.L series of 6.7 ~ 9.3 L much money is in China/the third and fourth stage of the road mobile machinery emission standard Accurate medium horsepower engine, with its reliability and fuel economy. Intelligent three significant characteristics by the majority of users trust, widely used in infrastructure. Mines, ports, tunnels. In plateau and other applications, it is common to find equipment that has been used for more than 10,000 hours without major repair failure and is still in efficient attendance.

About the Cummins Engine Quality Control and

The quality control

Cummins Global Operating System (COS) practice;

Advanced production equipment and manufacturing technology, such as AVL thermal test bench, Atlas tightening tool, ABB automatic robot, etc.

Use Six Sigma as a problem solving tool;

Adopt advanced production equipment and manufacturing technology;

We have successfully passed the audit of GCIC quality management system and obtained the ISO9001 quality management system certification.

Strong IT system to support factory quality control;

A NGMES manufacturing system realizes assembly information, quality warning, part list, defect/repair record, deviation, TWO-DIMENSIONAL code tracing/error prevention and other functions in the production process;

B EASE system to achieve PFMEA, work instructions, process change, control plan management;

C CQMS system to achieve SCAR, assembly quality problem CAR, parts PPAP management;

D ToolsNet Electric tightening tool and assembly system monitors engine tightening torque, trend, SPC diagram, process capability, etc

E Gagetrak system realizes the calibration, verification and use state management of all gage in the factory.

Error prevention and traceability: a large number of scanning code, material lamp, sensor, sleeve selector, quality warning and so on for error prevention; Meanwhile, parts batch, measurement data and torque can be traced by scanning code, automatic detection and electric tightening tools.

Process inspection: periodic spot check on production process torque, bolt clamping force, hot oil test products, etc., and make SPC control chart;

Advanced quality laboratory: Measuring room, physical and chemical room and cleanliness room, measuring equipment is basically selected from the world famous brands, such as Zeiss, Mahr, Hommel, Millipore, Wilson, etc. Laboratory equipment mainly includes CMM, universal tool microscope, hardness tester, endoscope, roughness meter, ultrasonic instantaneous analyzer, cleanliness equipment, oil analysis equipment, etc.

Engine quality audit EQA: conduct monthly engine quality audit according to plan, and timely find early failure problems during engine operation

Guangxi Cummins industrial Power Co., Ltd. has assembly line, test line, coating line and auxiliary assembly line, the production area covers an area of 44989 square meters.

The assembly line is a highly automated production line. The Atlas electric tightening tool is used to ensure torque and control accuracy, and the Toolsnet system is used to manage and analyze tightening effects and process capabilities.

The production line adopts automatic equipment for assembly, and also uses a number of automatic online testing equipment, effectively ensure that the key characteristics of the engine is controlled.

Automatic valve clearance adjustment using Atlas technology, the system has automatic error prevention and data collection functions.

The test line is used for final engine inspection. The main inspection equipment is automatic AVL thermal test bench, black light detection and pre-assembly line before and after thermal trial assembly to achieve accurate detection and fully ensure the quality of each engine test.

The coating line mainly includes three parts: pretreatment, spray painting and post-spray painting. ABB spray paint robot is used for automatic painting and manual painting, which can automatically identify the engine model information, automatically select the paint track and color, and can be compatible with 7 different colors and realize automatic switching.

The auxiliary assembly line is mainly used for assembling the external parts of the engine. Atlas electric tightening gun is used for all final torque tightening on the production line, which can effectively ensure the tightening effect and process capacity of fasteners.

The entire production line adopts CMES manufacturing execution system, which is the next generation of Cummins manufacturing execution system, automatically prevents process errors, monitors the construction status of the engine in real time and collects the information of the engine construction process to fully ensure the quality of the engine process.