Categories

- Blog (58)

- News & Events (34)

Cummins ISG Engine Maintenance

Oil filter

• Operation method: (Actually, it needs to refer to factors such as road conditions and usage habits)

Oil change interval (whichever comes first)

heavy load medium load light load

Kilometers 75,000 100,000 100,000

Hours 1,500 2,000 2,000

Months 12 18 18

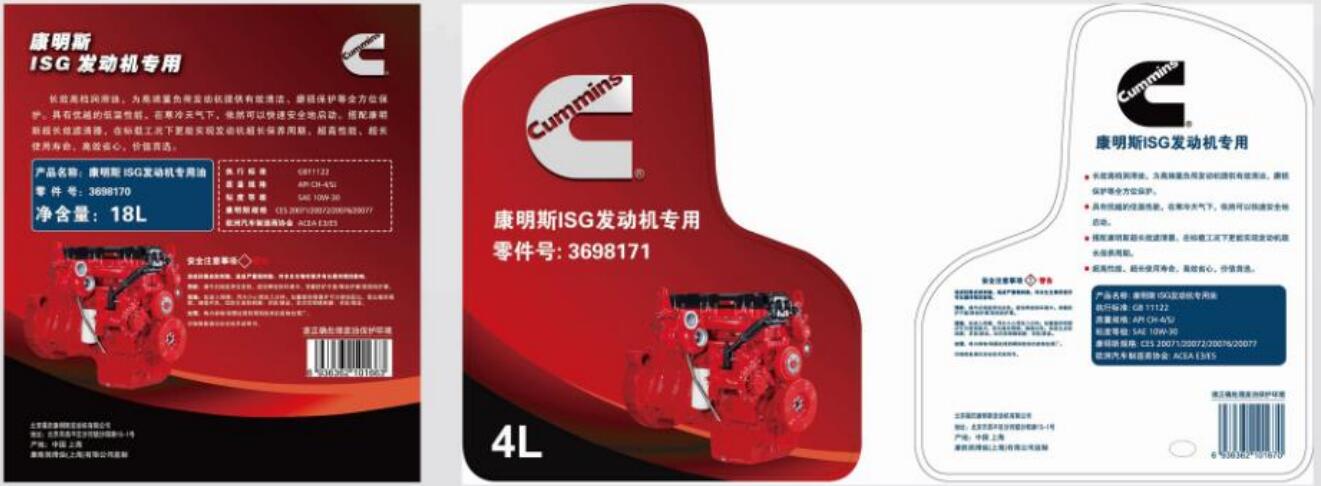

Oil standard ISG special oil, above CH level (including CH)

• Note: If the oil is changed within the 100,000 km maintenance period, the filter needs to be replaced at the same time.

1. Under the condition that you use the national IV standard diesel, the standard oil change interval of the ISG engine is 100,000 kilometers for maintenance. If the vehicle’s cargo weight is overloaded, it needs to be maintained at 75,000 kilometers in advance.

2. But for some areas in China, such as Hebei, Shandong and Shanxi, there are a lot of low-priced diesel oil. After investigation and analysis of oil samples in these areas, these low-priced diesel oil does not meet the National IV standard, and the sulfur content is very high. Excessive strong acid sulfides will be produced during the combustion process, which will accelerate the aging of the engine oil. In order to improve the operation efficiency and product life, it is recommended to use high-quality fuel from regular gas stations such as Sinopec and PetroChina. If high-quality fuel cannot be used due to objective conditions, please use CI grade ISG special oil, the engine oil replacement cycle is shortened to half of the standard, other things remain unchanged.

diesel filter

• Operation method: During engine maintenance, two diesel filters must be replaced at the same time, namely the oil-water separator and the fine filter. The oil-water separator is located on the girder and the fine filter is located on the engine. The maintenance period is 100,000 kilometers. (Actually, it needs to refer to factors such as road conditions and usage habits)

Air filter

• Precautions:

1. Replace every 20,000 kilometers or every 6 months (after repeated cleaning 6 times), subject to the relevant regulations of Foton Daimler! (Actually, it needs to refer to factors such as road conditions and usage habits)

Post-processing system

Urea solution

• Operation method: Check the urea level every day and add it at any time

• Precautions: Vehicle urea is a high-purity liquid urea solution with a concentration of 32.5%, with a freezing point of -11sC; regular urea must be used instead of agricultural urea or inferior urea, otherwise it will cause failure of the aftertreatment system.

Oil and gas separator

• Operation method: Installed on the girder, behind the urea tank, the vehicle needs to be replaced every 60,000 kilometers or 2,000 hours. (Actually, it needs to refer to factors such as road conditions and usage habits)

• Note: The location is on the girder, near the urea tank

• Disassembly:

1. Drain the vehicle air system;

2. Clean the area around the oil separator seat;

3. Use filter wrench to remove.

• Installation: replace the oil-air separator with a new one, coat the surface of the gasket with clean oil; install the oil-air separator properly

Aftertreatment Maintenance Requirements

Urea pump filter

• Operation method: Install in the urea dosing pump, pay attention to the round filter cover. The filter replacement cycle is 100,000 kilometers or 2,500 hours. (Actually, it needs to refer to factors such as road conditions and usage habits)

• Note: Location: On the urea pump above the urea tank

• Disassembly:

1. Use a 38mm wrench to turn the Ningdong filter cover counterclockwise;

2. Pull out the filter balance element (black part);

3. Pull out the filter element;

4. After replacing the filter element, install

• Install:

1. Use clean water to lubricate the filter sealing ring, prohibit the use of oil, which will contaminate the urea.

Urea tank filter

• Operation method: installed in the urea tank, and the filter element replacement cycle is 100,000 kilometers or 2,500 hours. (Actually, it needs to refer to factors such as road conditions and usage habits)

• Disassembly:

1. After turning the urea dosing pump counterclockwise a quarter turn, slowly lift the urea dosing pump and the liquid level sensor out of the urea tank

2. Squeeze inwards, unfasten the buckle, and remove the filter

Vehicle daily inspection items

Fuel oil water separator

• Operation method: Drain the oil-water separator before starting the vehicle every day, and drain the water and sediment in the oil-water separator

• How to:

1. Turn off the engine, manually rotate the drain valve at the bottom of the oil-water separator, turn it counterclockwise 3-4 turns, drain the water in the separator, until you see clean fuel, close the drain valve.

• Precautions:

1. Be careful not to over-tighten the drain valve, as over-tightening will damage the threads and affect the tightness.

Oil level

• Place the vehicle horizontally, measure the oil level before starting the vehicle or after 15 minutes of parking, pull out the oil dipstick, wipe it clean, insert it into the oil bottom, and then take it out to check the oil level, the normal oil page should be on the oil dipstick, between the lower scales.

• When the oil page is located in the middle of the upper and lower scale lines (the distance from the liquid level to the upper scale line is 7 grids), as shown in the figure, it is necessary to add oil, the filling amount is 4L, and the liquid level after adding is shown in the figure.

• Precautions

1. When it is found that the oil level is lower than the lower mark of the oil dipstick or higher than the mark of the oil dipstick, it is forbidden to start the diesel engine.

2. Must add ISG special oil, above CH level (including CH)

Coolant level

q Check the coolant level in the auxiliary water tank to see if it is within the proper range, check whether there is any leakage outside the diesel engine cooling system, and replenish it if necessary.

• Precautions:

1. Pure products must be added. Gold is directly added with water as coolant. Adding water directly will cause high water temperature failures, resulting in scale deposition and corrosion in the engine cooling system.

Exhaust Fluid Level

• When starting the vehicle every day, observe the urea liquid level indicator on the lower left of the instrument panel. When the alarm is found to be too low, please add urea in time to avoid affecting the power and economy of the vehicle.

• Precautions:

1. Please add pure products with a urea concentration of 31%-34%. When the urea concentration does not meet the standard, it will lead to failures such as vehicle weakness and poor economy.

Air filter

• Before starting the engine every day, check the air filter:

1. Whether there is dust, if so, clean it up in time;

2. Check whether the filter element is deformed or damaged. If the filter element is replaced in time, it will avoid affecting the power and economy of the vehicle;

• Precautions:

1. It is forbidden to run the engine without the filter element installed. The replacement of the air filter element of Sinotruk should depend on the environment of the vehicle.