Categories

- Blog (58)

- News & Events (34)

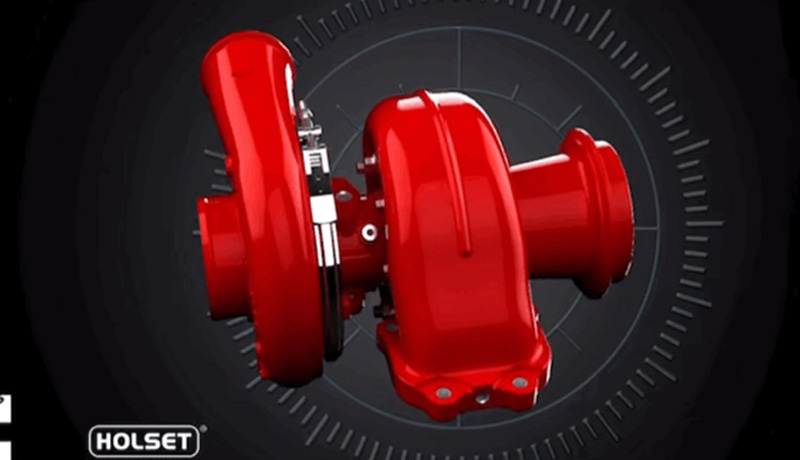

If the engine is the “heart” of the vehicle, the supercharger is the “lung” of the engine, which has a significant impact on power, fuel economy and emissions

Cummins launches N7 HE500 series fixed section and wastegate supercharger for heavy-duty diesel engine applications with innovative technology to help engines improve power, reduce fuel consumption and emissions

The new generation of products has a more compact structure design. Through the application of modular design, the basic platform can be customized according to needs, and technical features can be flexibly increased or decreased according to customer application scenarios. The product is suitable for engines with a displacement of 10-15 liters and different power ranges of 360-680 horsepower, and is optimized for the common engine speed range (900-1600RPM), suitable for various applications such as tractors and dump trucks

Structural optimization, process innovation, and efficient improvement of performance

The new generation of high-efficiency aerodynamic design optimizes key structures and innovates key processes, greatly improving reliability and accurately improving product performance.

Design parameters are adjusted through automatic optimization tools to further reduce exhaust energy loss.

Make full use of the engine exhaust pulse effect and make targeted optimization according to the engine operating conditions to help improve engine performance.

Excellent reliability and durability for complex working conditions

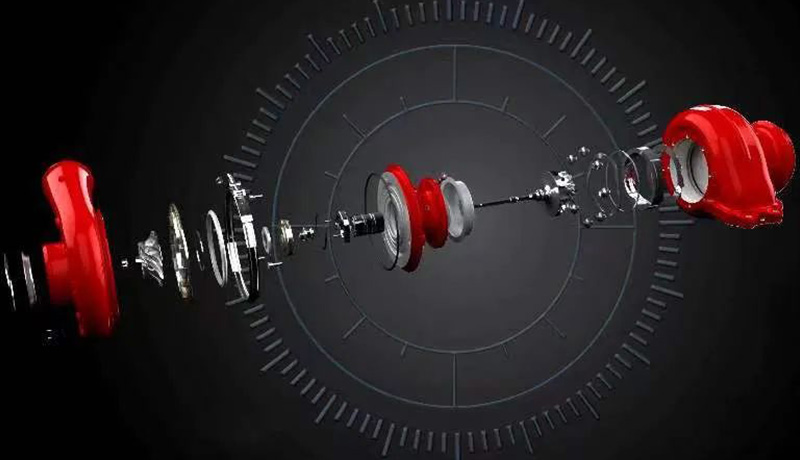

The technical application of lightweight turbine and impeller, combined with ball bearings, further reduces the weight of the gear train structure and reduces the moment of inertia.

Introduce new technology to enhance the fatigue resistance of the impeller.

The volute is automatically optimized by parameterization according to the reliability requirements, considering the high cycle fatigue risk in different modes; the outlet structure of the volute is optimized to reduce the efficiency loss and reduce the risk of air leakage.

It adopts a highly stable rotor system design, and integrates features such as thrust structure, pressure end connection, vortex end connection and vortex end seal.

Not only that, the new exhaust gas double bypass structure further balances the pressure and temperature between the two scroll passages, reduces the maximum temperature at the scroll end, and reduces the threat of scroll thermal fatigue. The unique Twin-D design further enhances product reliability.

More customizable “black technology” to help efficient attendance win in the future

The traditional diffuser structure has been subverted, bringing more extreme system performance improvements.

The radial dual-flow vortex end design with nozzle ring makes better use of the exhaust pulse energy of the engine and further improves the vortex end efficiency.

High-voltage electrochemical treatment significantly reduces the roughness of the flow channel, reduces the loss of air turbulence, and greatly improves the system efficiency.