Categories

- Blog (58)

- News & Events (34)

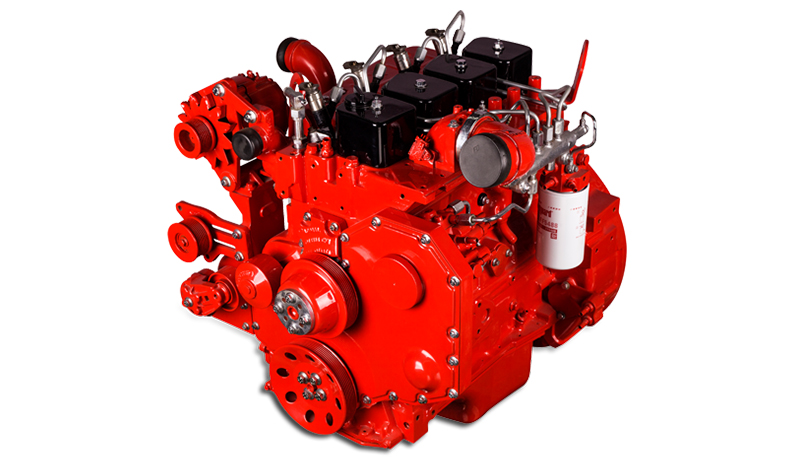

Cummins DCEC QSB3.9 pump engine

Type In-line four-cylinder, water-cooled, four-stroke, electronically controlled high pressure direct injection

Bore x Stroke (mm): 102 x 120

Displacement (liters): 3.9

Intake method: Turbocharger & intercool

Maximum power (hp/kW): 115/85

Maximum torque (N m): 520

Electronic control system: ECM

Fuel system: High pressure common rail system

Emissions: China III/EU Stage IIIA

Dry weight (kg): 331

L×W×H (mm): 778×753×882

Cummins DCEC QSB3.9 pump engine advantage

Supporting fields: fire protection, municipal administration, petrochemical, agriculture, etc.

• Advanced design and sophisticated manufacturing, adapt to a variety of harsh working conditions, high-strength, heavy-duty work ability

• The integrated design of the cylinder block and cylinder head prevents the occurrence of water leakage and oil leakage of the engine. The number of parts is about 40% less than that of other similar engines, and the failure rate is greatly reduced

• Adopt forged steel camshaft and crankshaft, high-strength cylinder block design, many parts are cast on the cylinder block, high rigidity, strong high pressure resistance, good reliability and longer service life

• Cylinder bore adopts platform mesh honing design, perfect geometric structure effectively prevents oil leakage, and adopts advanced technology such as new piston ring assembly and sealing gasket crimping molding, which reduces oil consumption

• Adopt Holset supercharger with integral wastegate, low-speed response and dynamic performance

• Three-stage fuel filtration ensures balanced particle dispersion levels, protecting major fuel system components and maximizing engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB3.9 pump engine models

Engine Model Rated Power/Speed kW/rpm Number of Cylinders Displacement L Weight Fuel System Intake Method

QSB3.9-P80 36@2900 4 3.9 281 Electronically controlled high pressure common rail booster intercooler

QSB3.9-P110 60@2900 4 3.9 281 Electronically controlled high pressure common rail Turbocharger & intercooler

QSB3.9-P115 85@2900 4 3.9 281 Electronically controlled high pressure common rail Turbocharger & intercooler

Cummins DCEC QSB3.9 engine for power generation

Type In-line four-cylinder, water-cooled, four-stroke, electronically controlled high pressure direct injection

Bore x Stroke (mm):102 x 120

Displacement (liters): 3.9

Intake method: turbocharger & intercool

Maximum power (hp/kW): 130/97

Maximum torque (N m): 520

Electronic control system: ECM

Fuel system: High pressure common rail system

Emission: China III

Dry weight (kg): 331

L×W×H (mm): 778×753×882

Cummins DCEC QSB3.9 G-drive engine advantages

• Advanced design and sophisticated manufacturing, adapt to a variety of harsh working conditions, high-strength, heavy-duty work ability

• The integrated design of the cylinder block and cylinder head prevents the occurrence of water leakage and oil leakage of the engine. The number of parts is about 40% less than that of other similar engines, and the failure rate is greatly reduced

• Adopt forged steel camshaft and crankshaft, high-strength cylinder block design, many parts are cast on the cylinder block, high rigidity, strong high pressure resistance, good reliability and longer service life

• Cylinder bore adopts platform mesh honing design, perfect geometric structure effectively prevents oil leakage, and adopts advanced technology such as new piston ring assembly and sealing gasket crimping molding, which reduces oil consumption

• Adopt Holset supercharger with integral wastegate, low-speed response and dynamic performance

• Three-stage fuel filtration ensures balanced particle dispersion levels, protecting major fuel system components and maximizing engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB3.9 G-Drive engine models

Engine Model Rated Power kW/rpm Reserve Power/RPM kW/rpm Number of Cylinders Displacement L Governor Type

QSB3.9-G3 79@1500 N/A 4 3.9 Electronic control 88@1500 N/A 4 3.9

QSB3.9-G2 63@1500 N/A 4 3.9 70@1500 N/A 4 3.9

Cummins DCEC QSB3.9 engine for construction machinery

Type In-line four-cylinder, water-cooled, four-stroke, electronically controlled high pressure direct injection

Bore x Stroke (mm):102 x 120

Displacement (liters): 3.9

Intake method: turbocharger & intercool

Maximum power (hp/kW): 130/97

Maximum torque (N m): 520

Electronic control system: ECM

Fuel system: High pressure common rail system

Emission: China III

Dry weight (kg): 331

L×W×H (mm): 778×753×882

Cummins DCEC QSB3.9 engine advantages

• Advanced design and sophisticated manufacturing, adapt to a variety of harsh working conditions, high-strength, heavy-duty work ability

• The integrated design of the cylinder block and cylinder head prevents the occurrence of water leakage and oil leakage of the engine. The number of parts is about 40% less than that of other similar engines, and the failure rate is greatly reduced

• Adopt forged steel camshaft and crankshaft, high-strength cylinder block design, many parts are cast on the cylinder block, high rigidity, strong high pressure resistance, good reliability and longer service life

• Cylinder bore adopts platform mesh honing design, perfect geometric structure effectively prevents oil leakage, and adopts advanced technology such as new piston ring assembly and sealing gasket crimping molding, which reduces oil consumption

• Adopt Holset supercharger with integral wastegate, low-speed response and dynamic performance

• Three-stage fuel filtration ensures balanced particle dispersion levels, protecting major fuel system components and maximizing engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB3.9 construction engine models

Engine Model Emission Standard Rated Power kW/rpm Maximum Torque N.m/rpm Number of Cylinders Displacement L Intake Mode

QSB3.9-C80-30 Country III/EU StageIIIA 60@2000 350@1350 4 3.9 Turbocharger & intercooler

QSB3.9-C80-31 Country III/EU StageIIIA 60@2200 350@1600 4 3.9 Turbocharger & intercooler

QSB3.9-C100-31 Country III/EU StageIIIA 74@2400 330@1600 4 3.9 Turbocharger & intercooler

QSB3.9-C110-30 Country III/EU StageIIIA 81@2200 480@1600 4 3.9 Turbocharger & intercooler

QSB3.9-C125-30 Country III/EU StageIIIA 93@2200 480@1350 4 3.9 Turbocharger & intercooler

QSB3.9-C130-30 Country III/EU StageIIIA 97@2300 520@1600 4 3.9 Turbocharger & intercooler

QSB3.9-C130-31 Country III/EU StageIIIA 97@2500 520@1600 4 3.9 Turbocharger & intercooler