Categories

- Blog (58)

- News & Events (34)

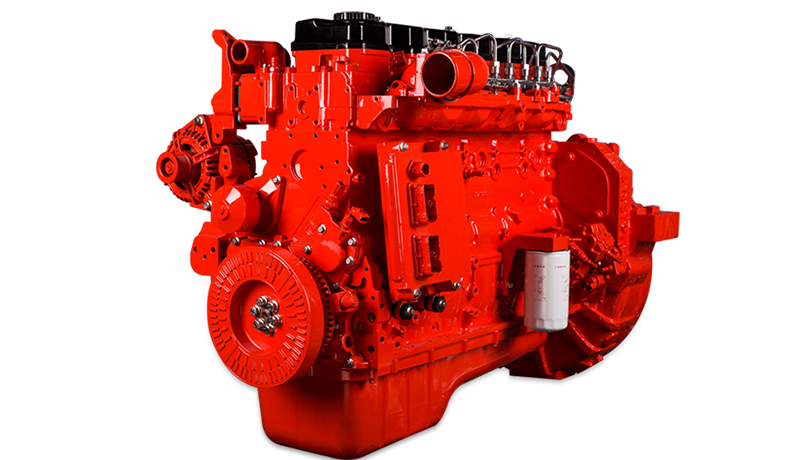

Cummins DCEC QSB6.7 pump engine

Type In-line six-cylinder, water-cooled, four-stroke, electronically controlled high-pressure direct injection

Bore x Stroke (mm): 107 x 124

Displacement (liters): 6.7

Intake method: Turbocharger & intercool

Maximum power (hp/kW): 230/170

Maximum torque (N m): 990

Electronic control system: ECM

Fuel system: High pressure common rail system

Emissions: China III/EU Stage IIIA

Dry weight (kg): 520

L×W×H (mm): 1150×810×910

Cummins DCEC QSB6.7 Pump Engine advantages

Supporting fields: fire protection, municipal administration, petrochemical, agriculture, etc.

• The five key systems of the engine are developed and optimized by Cummins to ensure the reliability of the engine

• High pressure common rail fuel system (HPCR), the fuel injection pressure is up to 1600bar, the throttle response is fast at different speeds, the power output is more efficient, the fuel economy is better, and the noise is lower

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to the application requirements, with stronger self-diagnosis and self-protection capabilities

• The filter system is redesigned for oil products, with strong fuel adaptability, suitable for applications in various fields

• Strong environmental adaptability, good cold start performance

• The overall modular design, the total number of parts is small, the failure rate is low, the structure is compact, and the maintenance is easy

• High-strength new cylinder design, increased displacement, better reliability, low noise and longer service life

• Adopt wastegate type turbocharger, the boost is smoother at low speed, and the power output is more stable at high speed

• Rear gear chamber power output with significant noise reduction effect

• Three-stage fuel filtration ensures balanced particle dispersion levels, protecting major fuel system components and maximizing engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB6.7 Pump Engine Models

Engine Model Rated Power/Speed kW/rpm Number of Cylinders Displacement L Weight Fuel System Intake Method

QSB6.7-P160 120@2900 6 6.7 520 Electronically controlled high pressure common rail supercharged intercooler

QSB6.7-P200 145@2900 6 6.7 520 Electronically controlled high pressure common rail supercharged and intercooled

QSB6.7-P230 170@2900 6 6.7 520 Electronically controlled high pressure common rail booster intercooler

Cummins DCEC QSB6.7 engine for power generation

Type In-line six-cylinder, water-cooled, four-stroke, electronically controlled high-pressure direct injection

Bore x Stroke (mm): 107 x 124

Displacement (liters): 6.7

Intake method: Turbocharger & intercool

Maximum power (hp/kW): 260/194

Maximum torque (N m): 990

Electronic control system: ECM

Fuel system: High pressure common rail system

Emission: China III

Dry weight (kg): 520

L×W×H (mm): 1150×810×910

Cummins DCEC QSB6.7 engine for generator set advantages

• The five key systems of the engine are developed and optimized by Cummins to ensure the reliability of the engine

• High pressure common rail fuel system (HPCR), the fuel injection pressure is up to 1600bar, the throttle response is fast at different speeds, the power output is more efficient, the fuel economy is better, and the noise is lower

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to the application requirements, with stronger self-diagnosis and self-protection capabilities

• The filter system is redesigned for oil products, with strong fuel adaptability, suitable for applications in various fields

• Strong environmental adaptability, good cold start performance

• The overall modular design, the total number of parts is small, the failure rate is low, the structure is compact, and the maintenance is easy

• High-strength new cylinder design, increased displacement, better reliability, low noise and longer service life

• Adopt wastegate type turbocharger, the boost is smoother at low speed, and the power output is more stable at high speed

• Rear gear chamber power output with significant noise reduction effect

• Three-stage fuel filtration ensures balanced particle dispersion levels, protecting major fuel system components and maximizing engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

• Mature intelligent electronic control technology improves the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB6.7 G-Drive Engine Models

Engine Model Rated Power kW/rpm Reserve Power/RPM kW/rpm Number of Cylinders Displacement L Governor Type

QSB6.7-G4 168@1500 N/A 6 6.7 Electronic control 185@1500 N/A 6 6.7

QSB6.7-G3 151@1500 N/A 6 6.7 166@1500 N/A 6 6.7

Cummins DCEC QSB6.7 engine for construction machinery

Type In-line six-cylinder, water-cooled, four-stroke, electronically controlled high-pressure direct injection

Bore x Stroke (mm): 107 x 124

Displacement (liters): 6.7

Intake method: Turbocharger & intercool

Maximum power (hp/kW): 260/194

Maximum torque (N m): 990

Electronic control system: ECM

Fuel system: High pressure common rail system

Emissions: China III/EU Stage IIIA

Dry weight (kg): 520

L×W×H (mm): 1150×810×910

Cummins DCEC QSB6.7 Constriction engine advantages

•The five key systems of the engine are developed and integrated by Cummins to ensure the reliability of the engine

• High pressure common rail fuel system (HPCR), the injection pressure is up to 1600bar, the throttle response is fast at different speeds, the power output is more efficient, the fuel economy is better, and the noise is lower

•Mature intelligent electronic control technology can improve the overall performance of the engine, and the engine specifications can be customized according to application requirements, with stronger self-diagnosis and self-protection capabilities

• Redesign the filter system for oil products, with strong fuel adaptability, suitable for applications in various fields

• Strong environmental adaptability, good cold start performance

• Overall modular design, less total number of parts, low failure rate, compact structure, easy maintenance

•High-strength new cylinder design, increased displacement, better reliability, low noise and longer service life

•Using a wastegate turbocharger, the boost is smoother at low speed, and the power output is more stable at high speed

• The power output of the rear gear chamber has a significant noise reduction effect

•Three-stage fuel filter ensures a balanced particle dispersion level, protects the main components of the fuel system, and maximizes engine life

• The electronic control system can intelligently switch the working mode according to the environment and operating conditions, and has the functions of self-diagnosis, alarm and remote monitoring

•Mature intelligent electronic control technology can improve the overall performance of the engine, and the engine specifications can be customized according to application requirements

Cummins DCEC QSB6.7 Constriction engine model list

Engine Model Emission Standard Rated Power kW/rpm Maximum Torque N.m/rpm Number of Cylinders Displacement L Intake Mode

QSB6.7-C130-30 Country III/EU StageIIIA 99@2200 580@1400 6 6.7 Supercharged intercooler

QSB6.7-C155-30 Country III/EU StageIIIA 116@2200 622@1500 6 6.7 Supercharged intercooler

QSB6.7-C160-31 Country III/EU StageIIIA 119@2500 732@1500 6 6.7 Supercharged intercooler

QSB6.7-C170-30 Country III/EU StageIIIA 129@2200 800@1500 6 6.7 Supercharged intercooler

QSB6.7-C190-30 Country III/EU StageIIIA 142@2200 931@1400 6 6.7 Supercharged intercooler

QSB6.7-C190-31 Country III/EU StageIIIA 145@2050 930@1300 6 6.7 Supercharged intercooler

QSB6.7-C205-30 Country III/EU StageIIIA 153@1800 929@1300 6 6.7 Supercharged intercooler

QSB6.7-C215-30 Country III/EU StageIIIA 158@2000 962@1300 6 6.7 Supercharged intercooler

QSB6.7-C215-31 Country III/EU StageIIIA 160@2500 888@1500 6 6.7 Supercharged intercooler

QSB6.7-C220-30 Country III/EU StageIIIA 163@2200 949@1500 6 6.7 Supercharged intercooler

QSB6.7-C220-31 Country III/EU StageIIIA 164@2000 950@1250 6 6.7 Supercharged intercooler

QSB6.7-C240-30 Country III/EU StageIIIA 178@2200 970@1500 6 6.7 Supercharged intercooler

QSB6.7-C240-31 Country III/EU StageIIIA 178@2000 970@1400 6 6.7 Supercharged intercooler

QSB6.7-C250-30 Country III/EU StageIIIA 186@2200 990@1500 6 6.7 Supercharged intercooler

QSB6.7-C260-30 Country III/EU StageIIIA 194@2200 990@1500 6 6.7 Supercharged intercooler

QSB6.7-C260-31 Country III/EU StageIIIA 194@2400 990@1501 6 6.7 Supercharged intercooler