Categories

- Blog (58)

- News & Events (34)

Weekly maintenance content (including daily maintenance content)

★ When the core is not installed, the engine cannot be started. Be careful not to damage the filter element when removing it

250 hours of operation, 16,000 km or 6 months of maintenance

In addition to the full content of daily and weekly maintenance, this maintenance item also includes the following:

change fuel filter

The maximum intake resistance of the engine is 635mmH2O, and the air resistance can be judged by the resistance indicator on the right. The filter element should be serviced or replaced when the red mark (2) rises to the window (1). Then, press the button at (3) to reset the indicator mark (2)

● The paper filter element (6) in the dry air filter can be purged from the inside to the outside with compressed air with a pressure not higher than 500KPa. The nozzle should not be too close to the paper when purging. The 5-purge filter element must be replaced. The filter element must be replaced if the filter element has holes, cracks, loose or indented seals and other factors that can cause air bypass.

● If an air compressor is installed, the moisture in the air receiver should be drained weekly

Remove the filter element, unscrew the filter element in the direction shown in the figure, and take off the sealing ring on the thread of the inner ring and the large sealing ring on the outer circle.

Wipe the surface where the filter is installed on the filter holder with a clean silk cloth

● Replace the fuel filter element with oil-water separation function produced by Fleetguard Company. Apply a small amount of oil to the sealing surface, fill the filter with clean fuel, and install the filter element. Tighten it in the direction shown in the figure. When the sealing ring touches the seat, turn it 1/2 to 3/4 turn. Overtightening will damage threads and cores Change oil and oil filter

★Try not to use the screw plugs on both sides to drain the oil, it will not drain completely. Do not extend the oil change interval, otherwise the engine life will be affected.

● Remove the oil filter, wipe the underside of the filter seat, and fill the new filter with new oil. Install in the same way as the fuel filter

q Dry the oil drain plug and replace the oil pan. Fill in new oil until the correct position is where the oil level is between the H and L marks on the dipstick.

● Start the engine to run, check for leaks, and pay close attention to the oil pressure reaching the normal position within 15 seconds. Shut down for about 10 minutes and then check whether the oil level is between the H and L marks on the oil dipstick. Check or replace the crankcase breather. Disassemble the breather and clean all metal parts and rubber parts in the specified washing solvent. Then blow dry thoroughly with compressed air. Check the rubber gasket and replace if necessary. Inspect the body and cover for cracks, dents, and damage; discard unusable parts. Check the heat exchanger zinc plug Remove and inspect the zinc plug on the heat exchanger or marine gearbox cooler, if the zinc electrode is lost to less than 1/2 its diameter and length, it should be replaced with a new one.

1500 hours of operation or 1 year warranty

In addition to the 250-hour maintenance items, the maintenance content of this item also includes the following items:

● Adjust valve clearance and injector stroke (or torque)

● Torque of supercharger mounting nut

● Torque of engine mounting bolts

● Shutters and temperature-controlled fans

● Check the water pump and clean the drip hole of the water pump

● Change engine coolant

4500 hours of operation or 2 years warranty

In addition to the full contents of the 1500-hour maintenance, this maintenance item also includes the following:

● Clean and recalibrate fuel pumps and injectors

Run the engine until the water temperature reaches 60°C, stop and remove the oil drain plug at the bottom of the oil pan to drain the oil. Check or replace the water pump

● Check or replace supercharger and shock absorber

● Check or replace the air compressor

● Check crankshaft axial clearance

● Check the fan tensioner and fan hub, add grease

● Clean the cooling system and replace the coolant

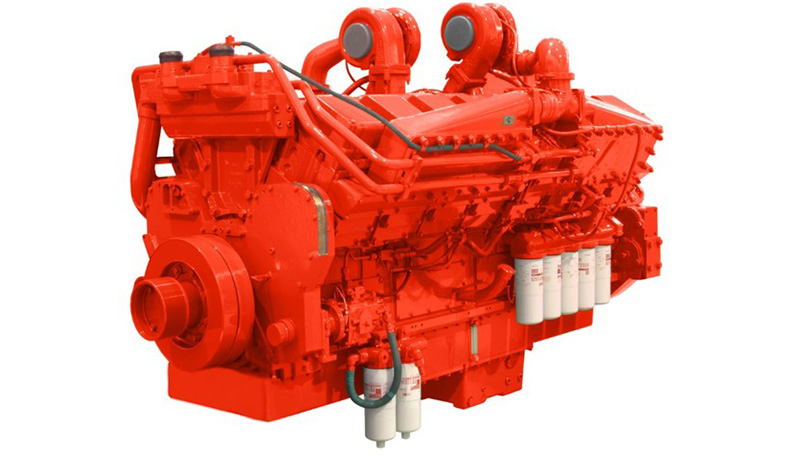

Above, we have introduced the general methods of using and maintaining Cummins engine to you, hoping to help you use and maintain the engine properly. Preventive maintenance can create great wealth by keeping the engine running efficiently with the least amount of money