Categories

- Blog (58)

- News & Events (34)

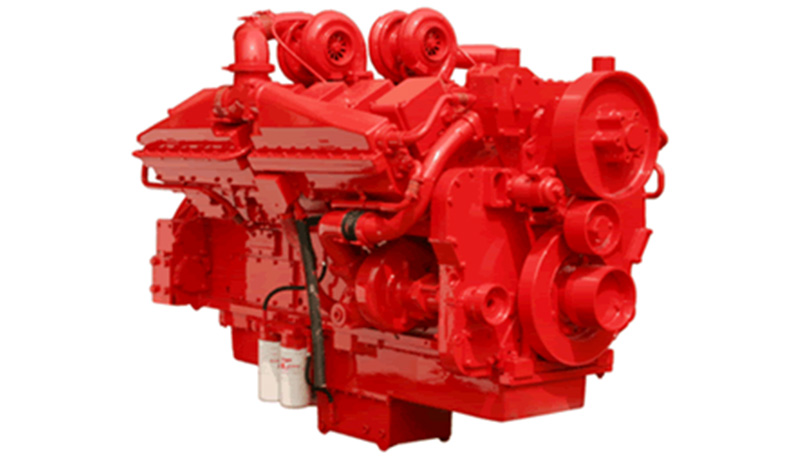

Summary of Cummins Engine Use and Maintenance

Instructions for Cummins CCEC Engine use

The operator of the engine must assume the responsibility of maintaining and maintaining the engine during the use of the engine, so that the Cummins diesel engine can provide you with the best service.

OVERVIEW: THE FOLLOWING ENGINES FOR ALL PURPOSE

—-Instructions before starting the new engine

1. Fill the fuel system

A. Add clean diesel fuel to the fuel filter, and the diesel specifications should meet the national standards.

b. Check the tightness of the oil inlet line.

c. Check and fill fuel tank.

2. Fill the lubrication system

A. Remove the oil inlet pipe from the supercharger, lubricate the supercharger bearing with 50~60ml of clean lubricating oil, and then reinstall the oil inlet pipe.

b. Fill the crankcase with oil to between the low (L) and high (H) positions on the dipstick. The original oil dipstick must be used for the oil pan or engine.

3. Check the air line connections

Check the tightness of the air compressor and air equipment (if equipped) and the air intake and exhaust system, and all clamps and joints should be tightened.

4. Check and add coolant

A. Remove the radiator or heat exchanger cap and check the engine coolant level. Add if necessary.

b. Check for coolant leaks; open DCA water cleaner shut-off valve (from OFF to ON)

—The running-in of the new engine

Cummins engines are test-run on a dynamometer prior to shipment from the factory and are therefore ready for immediate service. However, the longest service life can be obtained if the operator operates under the following conditions during the first 100 working hours.

1. Run the engine below 3/4 throttle load for as long as possible.

2. Avoid idling the engine for extended periods of time or at maximum horsepower for more than 5 minutes.

3. Get into the habit of paying close attention to the engine instrumentation during operation. If the oil temperature reaches 121°C or the coolant temperature exceeds 88°C, you should turn off the accelerator.

4. During the run-in period, check the oil level every 10 hours.

Maintenance and Maintenance Requirements of Cummins CCEC Diesel Engine

Air intake system

– must ensure that the intake system is clean

– Check the intake system for possible leaks

– Regularly check the pipes and clamps for damage and looseness

——Maintain the air filter element according to the environmental dust pollution and the indication of the air intake resistance indicator, and check the rubber sealing ring and filter paper of the air filter element to ensure that it is in the best condition

——If you use compressed air to clean the air filter element, it must be purged from the inside to the outside, and the compressed air pressure should not exceed 500KPa,

To avoid damage to the filter element, the filter must be replaced after cleaning more than 5 times.

★ Dangerous! Dust ingress can damage your engine!

Lubrication system

——Oil recommendation

When the ambient temperature is higher than -15°C, use SAE15W40, API CF4 or higher oil; when the temperature is between -20°C and –15°C, use SAE10W30, API CF4 or higher oil. Use SAE5W30, API CF4 or higher oil when the air temperature is between -25°C and -20°C. Use SAE 0W30, API CF4 or higher oil when the air temperature is between -40°C and -25°C.

——Before starting the engine every day, the oil level must be checked, and the oil must be replenished when the oil is lower than the L mark on the oil dipstick

—— Change the oil filter every 250 hours, and the oil filter must be filled with clean oil when changing the oil filter

——Change the oil every 250 hours. When changing the oil, pay attention to check the magnetic core of the oil drain plug. If a large amount of metal is adsorbed, please stop using the engine and contact the Chongqing Cummins service network

——When replacing the oil and filter, it should be carried out in a warm state, and be careful not to let dirt enter the lubrication system

– Use only Cummins approved Fleetguard filters

Fuel System

——Select high-quality high-quality light diesel oil according to ambient temperature conditions

——After the daily shutdown, the water and sediment in the oil-water separator should be discharged in the hot state

——The fuel filter must be replaced every 250 hours, and the fuel filter must be filled with clean fuel when changing the fuel filter

——Only use the Fleetguard filter approved by Cummins, do not use low quality non-Cummins filter, otherwise it may cause serious failure of the fuel pump and injector

——Be careful not to let dirt enter the fuel system when changing the filter

——Check the fuel tank regularly, and clean the cooling system as soon as the fuel tank is found to be dirty

——Danger: When the engine is still hot, do not open the radiator cap to avoid personal injury

– Check the coolant level before starting the engine every day

– Change the water filter every 250 hours

——If the ambient temperature is lower than 4°C, the cooling (antifreeze) liquid recommended by Chongqing Cummins must be used (well proportioned), which can be used in an environment above -40°C and can be used continuously 1 year

– Fill the coolant up to the neck of the water tank or expansion tank

——During the use of the engine, the pressure sealing condition of the water tank should be kept in good condition, and the cooling system should ensure that there is no leakage, otherwise the boiling point of the coolant will decrease, which will affect the performance of the cooling system

– Coolant must contain an appropriate amount of DCA to prevent liner cavitation and cooling system corrosion and fouling Operators

Normal starting requirements

The starter motor should not run for more than 30 seconds at a time, and should wait 2 minutes when starting again

The oil pressure should reach 70kpa within 15 seconds after starting, otherwise, immediately stop and check

After starting, the load can only be added after idling for 3-5 minutes. Otherwise, the parts such as bearing bushes will be caused by an instant lack of oil supply.

Excessive wear

The idling speed should not exceed 10 minutes. Long-term idling will cause oil leakage of the supercharger, carbon deposition in the cylinder, and increased wear and tear of components.

The engine water temperature should not be lower than 60°C, otherwise the fuel will enter the crankcase through the inner wall of the cylinder to dilute the lubricating oil, and the water temperature can be raised by increasing the speed

After starting in winter, keep idling until the pointer of the water temperature gauge rotates or start running after 10 minutes, and pay attention to the changes of the water temperature gauge and oil pressure gauge. When using auxiliary starting fluid in winter, it must be accurately measured.

Operating requirements

Always observe the instrument during engine operation to confirm that the engine water temperature is not lower than 60°C and not higher than the set alarm temperature, and the oil pressure at idle speed should be greater than the specified value (83KPa for M11, 138KPa for KT19, 103KPa for NT)

If the engine is overheated, the load should be reduced, and if the engine is still overheated after reducing the load for a period of time, it should be stopped and checked.

Pay close attention to the following changes in the engine during operation. If any item changes suddenly, it is likely to be a harbinger of failure, please check and repair in time

□ Engine stall or misfire

□ Abnormal vibration

□ The engine has abnormal noise

□ Sudden changes in engine working pressure and temperature

□ Engine exhaust smoke is too high

□ Engine power drops

□ Increased oil consumption

□ Increased fuel consumption

□ Fuel, oil or coolant leakage

Downtime requirement

● Before shutting down the engine, it should run at idle speed for 3-5 minutes, otherwise the supercharger, piston, cylinder and other parts may be easily damaged. The engine operating range

● When the engine is lower than the maximum torque speed, the full throttle operation should not exceed 30 seconds. Otherwise, the life of the engine will be shortened and serious damage to the engine may occur. Cummins engines are designed to work best above the maximum torque rpm point, so it is recommended to run the engine in this range

● Under no circumstances or circumstances should the engine run above the maximum idle speed (the speed at which the engine is idling and the accelerator is fully open).

● When the car goes down a steep slope, the combination of the engine, the transmission and the brake must be used to control the vehicle speed and engine speed

★ Dangerous! Do not slide in neutral gear when the car is going downhill, otherwise it may cause the car to crash!

★ Dangerous! Do not close the fuel solenoid valve of the engine when the car is going downhill, otherwise it may cause the engine mechanical failure! daily inspection

● Check that the oil level of the oil dipstick should be between H and L. If it is lower than L, the engine must be refilled before running the engine.

● Drain water and impurities from the fuel filter every day

● Check the fan every day for cracks, deformation or loose rivets, otherwise the fan should be replaced. Never spin the engine by spinning the fan blades.

● Check whether the belt is tight and proper every day, and the grease does not fall on the belt. The belt can have small cracks, but it should be replaced when it has cross cracks, tears or chips. The belt surface is shiny to indicate that the belt is slipping and should be adjusted.

● Check whether the clamps of the intake pipe are firm and whether the hose connection is leaking. If so, it should be repaired immediately.

● When checking the coolant level, the coolant temperature must be lower than 50℃. Do not open the water tank cover when the temperature is high to avoid personal injury, and do not replenish the coolant when the temperature is high to prevent cracks in the castings. Fill coolant up to the neck of the filler neck.

● Check the appearance of the battery for dirt, and whether the connectors are loose and corroded

● If it is a marine engine, also check the seawater filter

warn! Do not add any other rust inhibitors, descaling agents, sealants, etc. to the cooling system, otherwise it may cause engine failure!