Categories

- Blog (58)

- News & Events (34)

Cummins CCEC QSK19 Engine Basic Specifications

Type Type: four-stroke, in-line six-cylinder

Air intake method: Turbocharger and intercooled

Displacement: 19L

Bore X Stroke: 159mm x 159 mm

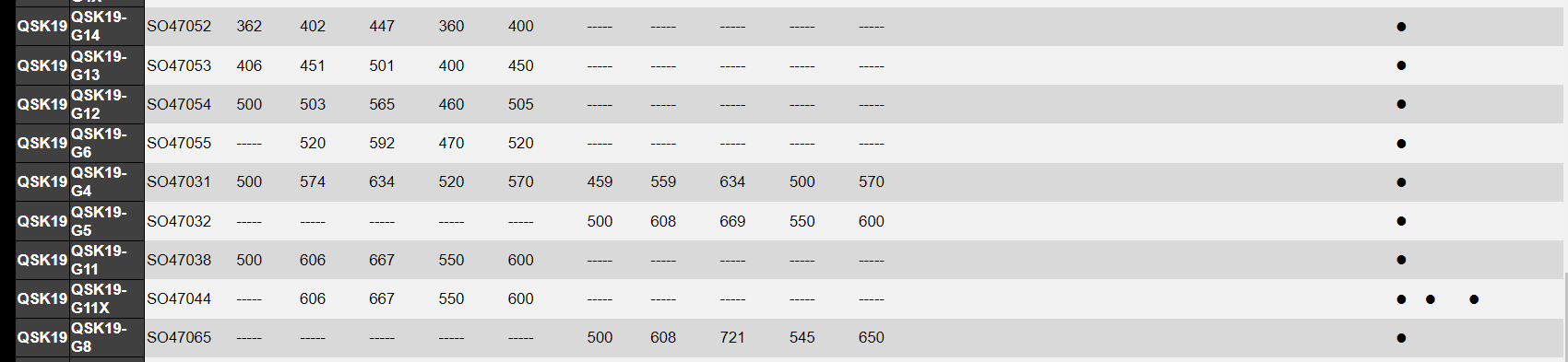

Performance characteristics of Cummins CCEC QSK19 series engine products

• Super power

The power ranges from 500 to 815 horsepower, and the maximum torque is 3086 N.m.

The self-weight is 1890 kg, and the power-to-weight ratio reaches 0.431 hp/kg.

• Low fuel consumption and good economy

Cummins PT fuel system, ultra-high injection pressure, ensures good atomization and complete combustion of the engine.

The high-efficiency Holset exhaust gas turbocharger can ensure more sufficient air intake, improve engine efficiency, further improve combustion, and reduce engine specific fuel consumption.

The air-to-air cooling technology ensures more sufficient air intake and better fuel economy.

• Compact structure, easy maintenance

The wet cylinder liner can be replaced, with good heat dissipation effect and easy replacement.

The spare parts of all models are highly versatile, highly serialized, and easy to maintain.

Both the cylinder body and the cylinder head adopt built-in pressure lubricating oil passages, with compact structure and low failure rate.

the

• Advanced design and reliable performance

Cylinder block: Made of high-strength alloy cast iron, with good rigidity, small vibration and low noise. the

Cylinder head: four-valve design per cylinder, optimized air-fuel mixture, effectively improving combustion and emissions. the

Camshaft: The single camshaft design can precisely control the valve and fuel injection timing, and the optimized cam profile can reduce the impact force, improve reliability and durability. the

Crankshaft: Integral crankshaft made of high-strength forged steel. The induction hardening process of rounded corners and journals can ensure higher fatigue strength of the crankshaft. the

Piston: Using the latest aluminum alloy casting technology, the ω-shaped head and barrel-shaped skirt design can compensate for thermal expansion and contraction to ensure a good fit.

• Professional configuration, excellent quality

Lubrication system: All moving parts are forced to lubricate; the large-capacity gear pump provides pressure lubricating oil to lubricate the bearing and cool the piston; the oil cooler, full-flow filter, and bypass filter ensure that the oil is kept in good condition. the

Fuel system: Cummins PT fuel system, optimized combustion, surging power; STC step-by-step timing system ensures better combustion under all working conditions; low-pressure fuel supply system, equipped with fuel one-way circuit, safe and reliable. the

Cooling system: forced water cooling by gear centrifugal water pump, large flow channel design, good cooling effect; spin-on water filter and special DCA additive can effectively control the acidity of the cooling liquid, prevent rust and cavitation and remove impurities. the

Intake and exhaust system: High-efficiency Holset exhaust gas turbocharger ensures adequate intake and improves combustion; pressure pulse exhaust pipe can make full use of exhaust gas energy and improve engine efficiency; air-to-air cooling technology ensures better fuel economy and better emissions.

• Mature products, well-known all over the world

Wide range of applications: QSK19 series engines are widely used in construction machinery, heavy-duty vehicles, power generation, ship power and other fields; and form strategic partnerships with important customers. the

High reputation: As one of the main models of the Cummins family, the QSK19 series engine has won high recognition from customers in various fields for its strong power, ultra-low fuel consumption, high reliability and low maintenance cost. the

Technology upgrade: air-to-air cooling, slow start and other technologies have further improved the engine’s reliability, power, fuel economy and emissions. The QSK19 engine adopts EFI technology and can meet the third-stage emission standard of non-road mobile machinery, which further strengthens CCEC’s leading position in China’s high-horsepower engine manufacturing industry.

Application of Cummins CCEC QSK19 Diesel engine

Maritime application

The marine engines produced by Chongqing Cummins are mainly used in the main propulsion of various ships such as trawlers, ferries, working boats, tugboats, fishery administration ships, firefighting boats, passenger ships, and small and medium-sized transport ships, as well as auxiliary power of various ocean-going transport ships. .

The marine engines produced by Chongqing Cummins have passed the emission certification of the International Maritime Organization (IMO), and passed the certification of China Classification Society (CCS) and International Classification Society (BV).

Generate electricity application

The power range of engines for power generation produced by Chongqing Cummins is 200-1112kW. Widely used in buildings, telecommunications, ships, field construction, industrial electricity and other fields.

Typical applications include Antarctic Zhongshan Station, UN peacekeeping projects, China Telecom, China Mobile, CCTV, Xichang Satellite Launch Center, Qinghai-Tibet Plateau Railway Construction, etc.

The advanced economy, power, reliability, durability and environmental safety of Chongqing Cummins engines are widely welcomed by users at home and abroad.

Industry application

Chongqing Cummins engines are widely used in bulldozers, track machinery, power units, petroleum machinery, road machinery, mining machinery, air compressors and other construction machinery fields.

We have established close strategic partnerships with major construction machinery manufacturers.

Chongqing Cummins N series and M11 series engines can meet the second stage (Tier II) emission standards for non-road mobile machinery, and the QSK series engines launched in 2008 can meet the third stage (Tier III) emission standards for non-road mobile machinery.